Discover how our latest technologies can optimize your workflow and meet your specific needs.

In this edition of MicroSupport News, we introduce three innovative tools and applications designed to enhance micro-

handling, precision processing, and advanced sampling techniques. Each solution is developed to improve efficiency, accuracy,

and usability in various research and industrial applications.

Featured Technologies in This Issue

Introducing a method for precisely transferring inorganic microparticles to a designated location, such as carbon tape, for elemental analysis.

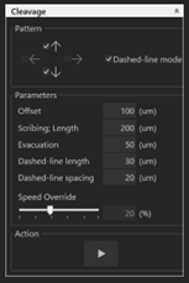

For organic materials, collection is typically done using a metal probe. However, with inorganic materials, electron charges often

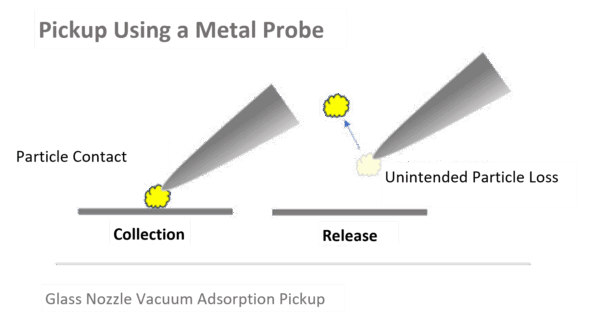

cause particles to repel when the probe is brought close. To address this issue, we propose utilizing a method vacuum adsorption

at the tip of a glass nozzle for safe and precise transportation, as shown in the example below.

By using this method, the risk of losing valuable microparticles is significantly reduced, and damage to the substrate is minimized, enabling precise sampling.

For more information, please click this link >>> Glass Nozzle (Tool) / Vacuum Adsorption Tool Set

Since the nozzle used in this method is made of glass,careful and delicate handling is required. To prevent breakage and ensure precise positioning, we recommend using it in combination with the micromanipulator.

For more information, please click this link >>> Micromanipulator

Application Methods for Microliter Liquids and Pastes

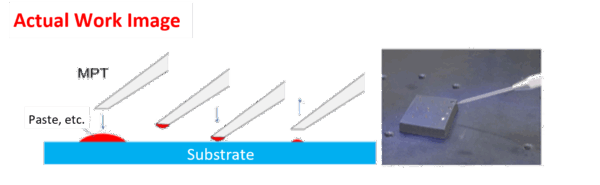

When handling small volumes of low-viscosity liquids, it is preferable to use a micropipette in combination with a micro-injector for controlled dispensing. However, this method poses challenges when dealing with viscous or paste-like liquids, as they are highly difficult to aspirate and release. To address this, we utilize a specially designed micro-tool that enables an efficient transfer method for such substances.

Proposed Transfer Solution Using Specialized Tools & Manipulators

The specialized micro tool used in this method has the following specifications:

Product Name: Glass Micro Press Tool

Model: MPT (Used in conjunction with the dedicated hand unit MP-H)

Features: Custom processing for precise control of glass rod tips, allowing for diameters of ≦100 μm.

Precision positioning and controlled operations are required. For microscopic-scale transfer, manipulator-assisted work is essential.

By using this method, epoxy adhesives and Ag pastes can be precisely applied to targeted positions with a diameter of ≦100 μm. This technique is particularly effective for bonding MEMS components and fine circuit wiring.

In practice, workability may vary depending on factors such as the curing time of the applied liquid and the surface condition of the target material. For further details, please feel free to contact us.

For more information, please click this link >>> MPT

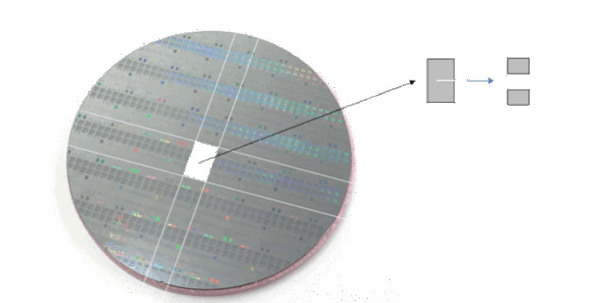

Microchip Scribing

When trimming large glass pieces or pre-cut sections to a specific size, it is common to use a diamond scriber manually along with a straight-bar or ruler for precision.

However, when performing final cutting at defect locations, even if the area can be visually identified under a microscope, achieving precise cutting at the micrometer level is extremely challenging.

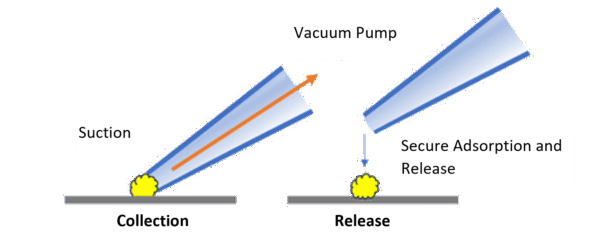

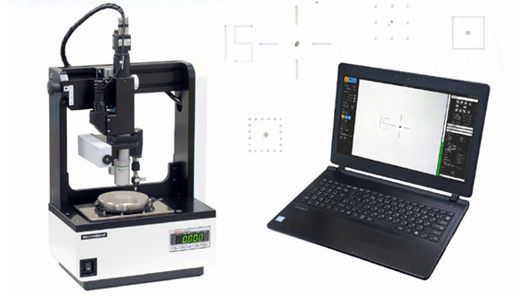

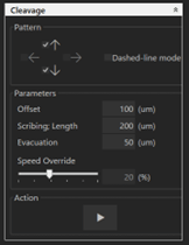

Our D-MARK marking system is equipped with a cleaving mode, enabling high-precision line scribing. For example, on wafer

chips of 〜10mm, it can create scribing lines with an accuracy of ≦5μm between the targeted and actual positions.

For more information, please click this link >>> D-MARK

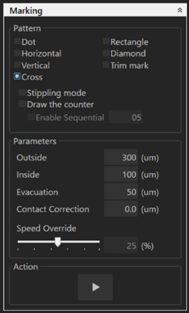

Marking and Scribe Modes Overview

Marking Mode |

Scribe Mode (Solid Line) The dashed-line box is unticked.  |

Scribe Mode (Dashed Line)

|

We also offer evaluation demos, so please feel free to consult with us.

In today’s work environment, where “work style reform” is unavoidable, standardizing operation steps, improving

efficiency and increasing productivity are unavoidable topics. Additionally, reducing dependency on individual workers

is a key challenge.

At MicroSupport, we assist users in overcoming these challenges by providing both hardware and software solutions.

From equipment selection advice to the development of custom tools, we offer comprehensive support tailored to your

needs.

Please contact us via the inquiry form for further assistance.