At MicroSupport, we regularly publish information on micro-handling and sampling through our “MicroSupport Newsletter.” We sincerely thank you for your continued interest and support of MicroSupport.

Feature 1: Which Microscope-Integrated System Suits You?

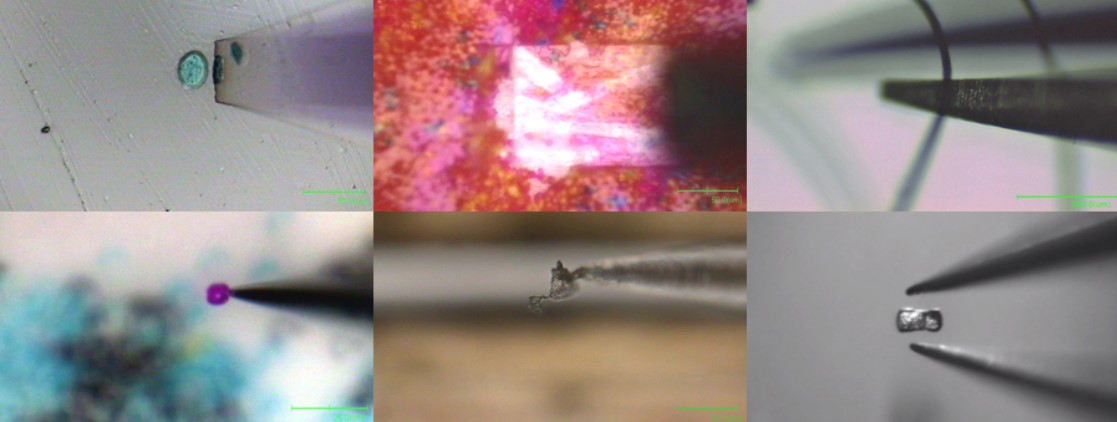

MicroSupport offers three variations of AxisPro: motorized microscope-integrated sampling systems:

We hope this provides a helpful reference during your evaluation.

Table 1 Feature comparison for most suitable model

| Feature Comparison | AxisPro FC | AxisPro F (FE) | AxisPro SS |

| Sampling Arm | Motorized | Motorized | Motorized |

| Focus Operation | Motorized | Motorized | Motorized |

| Sample Stage | Motorized | Motorized | Selectable / Optional |

| Transfer of Collected Sample | Motorized | Motorized | Motorized |

| Cover | Full Cover | N/A | N/A |

General Guidelines for Choosing a Model

・AxisPro FC – Recommended if you prioritize safety, a stable work environment, and operator comfort.

・AxisPro F – It operates the same as AxisPro FC, but without a cover. AxisPro FE is the Euro model.

・AxisPro SS – Recommended when customization is preferred or stages for unique samples are required.

We hope this provides a helpful reference during your evaluation.

Your selection may vary depending on your budget or required accessories for specific operations, so please feel free to consult us for more detailed recommendations.

Feature 2: Probes for Handling and Sampling

The AxisPro system enables precise handling and sampling of microscopic objects for analytical processing. Most importantly, selecting the most appropriate tool that suits the material condition and shape of the target sample is essential.

Table 2 Simplified guide for choosing the appropriate tool, with a special focus on glass-based options.

| Main Sample Type | Appropriate Micro-tool Material | ||

| Metal Type Probe | Glass Type Probe | Glass Type Pipette | |

| Organic Material | ◎ | △ | 〇 |

| Inorganic Material | △ | △ | ◎ |

| FIB Foils | ✕ | ◎ | 〇 |

◎ – Most suitable

〇 – Suitable

△ – Suitable depending on conditions (case by case)

✕ – Not suitable

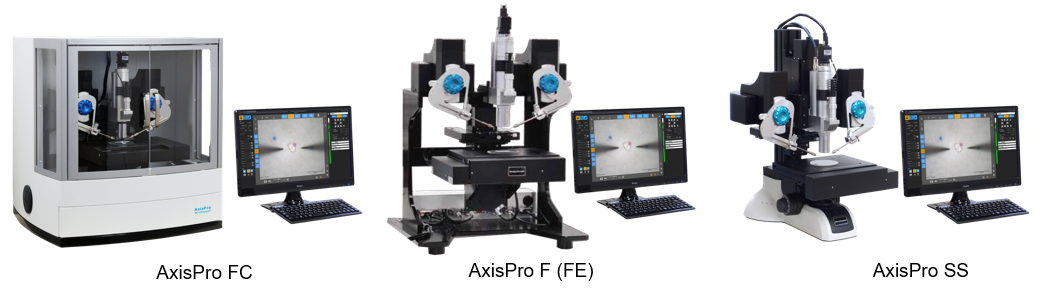

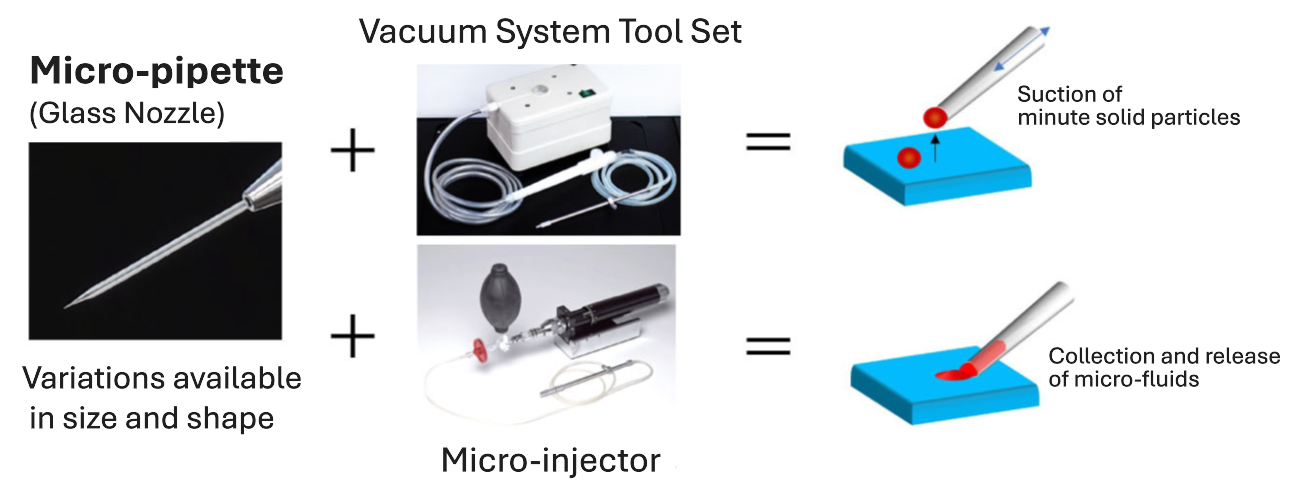

As shown, glass tools are available in two types: probe (needle-shaped) and pipette (pipe-shaped). In particular, for elemental analysis of inorganic materials using EDX(EDS) with SEM or TEM, or for lift-out of small FIB foils, glass tools are often more suitable.

Compared to metal probes, glass tools have smooth, rounded (R-shaped) tips, allowing for a larger contact area with the target object. This minimizes physical damage, such as scratches or deformation.

Additionally, glass pipette tools (used with vacuum suction or ultra-fine nozzle systems) can firmly capture objects, reducing the risk of particles loss.

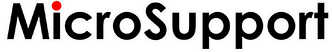

Image Descriptions:

We offer a wide range of glass tools in various shapes and sizes to match your working conditions.

In addition, glass pipettes are not limited to vacuum suction. They are also suitable for drawing in and releasing trace amounts of liquids or powders.

(Image below is for illustrative purposes)

Feature 3: Localized Observation and Processing in a Compact Body

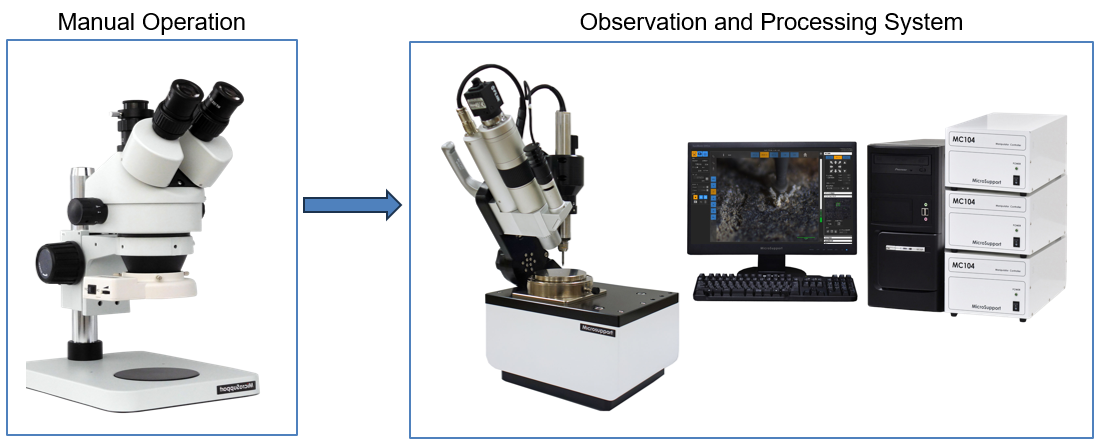

This time, in response to many customer requests for processing extremely small sample surfaces or internal sections during pre-analysis preparation, we would like to introduce our compact observation and processing tool; the “Milling Scope”, a tabletop milling and observation device.

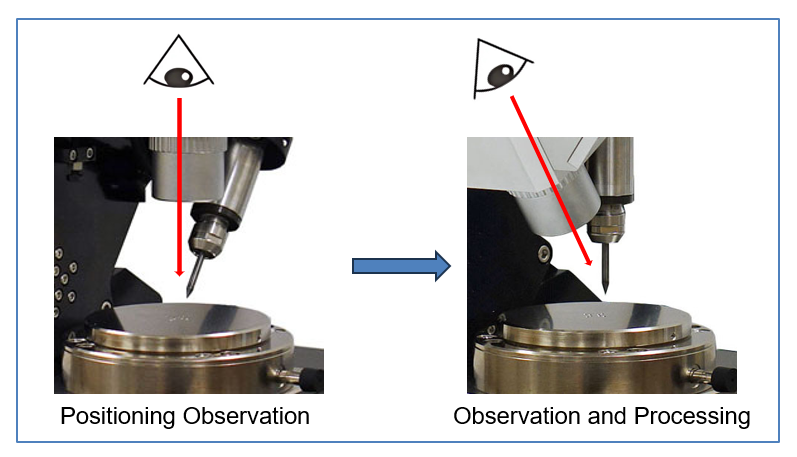

For fine surface or internal cutting of samples, this is often done manually under a stereomicroscope, as shown above, using handheld tools like micro-grinder. However, manual work makes it difficult to control cutting position or depth. Overcutting or losing the sample can occur, and results heavily depend on the operator’s experience and skill.

The Milling Scope allows users to check the cutting area from above and switch tools with a single operation, enabling safe and controlled processing while observing the sample in real time. It supports a wide range of materials including metals, semiconductors, minerals, bones, teeth, and more.

View our product – Milling Scope

Even when using only the micro-grinder, efficiency can be improved by setting it on our QuickPro unit.

View our product – Micro-grinder

Demo evaluations are available. Detailed brochures are also provided upon request.

Let Us Know Your Challenges or Concerns!

In today’s environment, where work efficiency is essential, themes such as streamlining operations and increasing productivity cannot be avoided.

At MicroSupport, we provide support from both hardware and software perspectives to help address the challenges our users face.

“If you’d like to try a demo” or “If you wish to further utilise your existing facilities,” please feel free to consult us.

From equipment selection advice to the creation of custom tools, we offer flexible support adapted to your needs.